|

[ Matchservo Motor VS. Induction Motor Vs. Brush Motor ]

|

Topic

|

Matchservo Motor

|

Induction Motor

|

DC Brush Motor

|

|

Compact Size, Light Weight

|

◎

|

X

|

△

|

Low Rotor Inertia,

High Speed Rotation

|

◎

|

△

|

X

|

|

No Rotor Copper Lose

|

◎

|

X

|

△

|

|

High Efficiency

|

◎

|

△

|

△

|

|

Heat Dissipation

|

◎

|

△

|

X

|

|

No Carbon & Electric Flash

|

◎

|

◎

|

X

|

|

Low Speed Torque

|

◎

|

X

|

△

|

|

No Brush maintenance

|

◎

|

◎

|

X

|

|

Over Load Capability

|

◎

|

X

|

△

|

|

◎ Excellent △ Acceptable X Poor

|

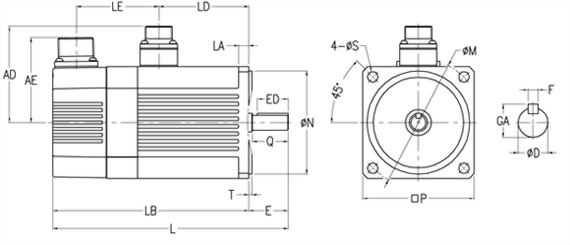

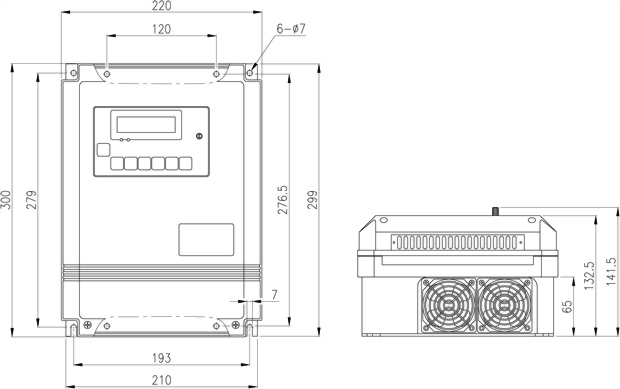

MA2 Servomotor Specification SD2 Servo Driver Specification MA4 Servomotor Specification

SD4 Servo Driver Specification Servo Motor Dimensions

Servo Driver Dimensions Performance Curve

|

|

|

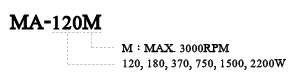

MA2

Servomotor Specification

|

|

|

|

|

|

|

120W

|

180W

|

370W

|

750W

|

1.5KW

|

2.2KW

|

3.7KW

|

5.5KW

|

7.5KW

|

|

Servormotor Model No.

|

MA2-120M/H

|

MA2-180M/H

|

MA2-370M/H

|

MA2-750M/H

|

MA2-1500M/H

|

MA2-2200M/H

|

MA2-3700M

|

MA2-5500M

|

MA2-7500M

|

|

|

M:0.38/H:0.19

|

M:0.57/H:0.29

|

M:1.18/H:0.59

|

M:2.39/H:1.2

|

M:4.782.39

|

M:7.17/H:3.59

|

11.78

|

17.5

|

23.8

|

|

|

M:1.16/H:0.57

|

M:1.73/H:0.87

|

M:3.53/H:1.77

|

M:7.18/H:3.6

|

M:14.0/H:7.17

|

M:20.3/H:10.76

|

29.4

|

43.75

|

59.5

|

|

|

M:0.65/H:0.6

|

M:0.9/H:0.8

|

M:1.95/H:1.6

|

M:3.5/H:3.0

|

M:7.6/H:6.5

|

M:12/H:10

|

18

|

24.5

|

32.0

|

|

|

M:1.17/H:1.8

|

M:2.5/H:2.4

|

M:5.88/H:4.8

|

M:10.2/H:9

|

M:22.8/H:18.5

|

M:36/H:30

|

45

|

61.3

|

80

|

|

|

M:3000/H:6000

|

|

Torque Constant-KT

|

N.m/

Arms

|

|

M:0.71/H:0.44

|

M:0.71/H:0.44

|

M:0.7/H:0.45

|

M:0.71/H:0.45

|

M:0.67/H:0.44

|

M:0.64/H:0.44

|

0.72

|

0.78

|

0.76

|

|

Rotor Moment of Inertia

10-4* kgm²

|

|

M:1.11/H:1.12

|

M:1.11/H:1.12

|

M:1.57/H:1.42

|

M:2.59/H:2.26

|

M:12.8/H:11.5

|

M:18.2/H:14.5

|

63.3

|

93.5

|

115

|

|

Mechanical Time Contant

|

ms

|

|

M:3.69/H:4.32

|

M:3.69/H:4.32

|

M:2.54/H:2.74

|

M:1.75/H:2.59

|

M:1.64/H:2.84

|

M:1.43/H:2.91

|

4.47

|

2.58

|

2.23

|

|

|

M:2.15/H:3.54

|

M:2.15/H:3.54

|

M:2.51/H:4.25

|

M:3.35/H:4.9

|

M:7.77/H:10.73

|

M:8.74/H:10

|

19.7

|

24.8

|

25.3

|

|

|

Class F

|

|

|

IP65(When an Oil

Seal is Used to be Fitted to the Rotating Shaft)

|

|

|

FIG A

|

FIG B

|

FIG C

|

FIG D

|

FIG E

|

FIG F

|

FIG G

|

FIG H

|

FIG I

|

|

|

M:2.4/H:2.4

|

M:2.4/H:2.4

|

M:3.9/H:3.1

|

M:4.7/H:4.3

|

M:10/H:9.1

|

M:12/H:10.5

|

20

|

25.5

|

29

|

|

|

|

|

|

|

|

|

|

|

|

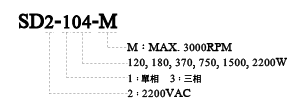

SD2

Servo Driver Specification

|

|

|

|

|

|

|

|

120W

|

180W

|

370W

|

750W

|

1.5KW

|

2.2KW

|

3.7KW

|

5.5KW

|

7.5KW

|

|

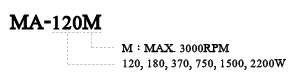

Drive model No.

|

SD2-101M/H

|

SD2-102M/H

|

SD2-104M/H

|

SD2-107M/H

|

SD2-115M/H

|

SD2-122M/H

|

SD2-337M

|

SD2-355M

|

SD2-375M

|

|

|

MA2-120M/H

|

MA2-180M/H

|

MA2-370M/H

|

MA2-750M/H

|

MA2-1500M/H

|

MA2-2200M/H

|

MA2-3700M

|

MA2-5500M

|

MA2-7500M

|

|

|

220V±10% 1Ø

|

220V±10% 3Ø

|

|

|

50/60

|

|

Rated Output Current

|

Arms

|

|

M:0.65 / H:0.6

|

M:0.9 / H:0.8

|

M:1.95 / H:1.6

|

M:3.5 / H:3.0

|

M:7.6 / H:6.5

|

M:12 / H:10

|

18

|

24.5

|

32.0

|

|

|

M:1.7 / H:1.8

|

M:2.5 / H:2.4

|

M:5.88 / H:4.8

|

M:10.2 / H:9.0

|

M:22.8 / H:18.5

|

M:36 / H:30

|

45

|

61.3

|

80

|

|

Encoder Type and Resoluation

|

|

A,B,Z,HU,HV,HW Open Collector. (A,B Phase=

128PPR)

|

|

|

0.1~60.0 Sec.

|

|

Speed

Regulation

|

Load

|

±

0.3% Below (0~Rated Torque at Rated Speed)

|

|

Voltage

|

±

0.3% Below (Source Voltage ± 10%at Rated Speed no Load)

|

|

Temperature

|

±

0.3% Below (0~45°C /32~113°F at Rated Speed no Load)

|

|

|

Sin PWM

|

|

|

1.Speed model

2.Torque mode 3.Position mode

|

|

Input

Signal

|

Analog Panel

|

1.Vref, Tref ±10V Analog Input 2.Panel VR 0~5V Analog Input

|

|

Digital Panel

|

D10~D16 and COM common, Input Impedance 4.7KΩ to

common

|

|

|

DOx Open

Collector (x=0~3), External Voltage(48VDC, 10mA below).

Magnet brake relay please set at DO3.

|

|

|

Overload, Over

Current, Over Voltage, Over Heat

Encoder Abnormal, Short Circuit

|

|

|

FIG 1

|

FIG 1

|

FIG 1

|

FIG 1

|

FIG 2

|

FIG 2

|

FIG 3

|

FIG 3

|

FIG 3

|

|

|

1.1

|

1.1

|

1.1

|

1.1

|

1.3

|

1.3

|

5

|

6

|

6

|

|

|

|

|

|

|

|

|

|

MA4

Servomotor Specification

|

|

|

|

|

|

|

|

750W

|

1.5KW

|

2.2KW

|

3.7KW

|

5.5KW

|

7.5KW

|

|

Servormotor M

|

MA4-750M/H

|

MA4-1500M/H

|

MA4-2200M/H

|

MA4-3700M

|

MA4-5500M

|

MA4-7500M

|

|

|

M:2.39 / H:1.2

|

M:4.78 / H:2.39

|

M:7.17 / H:3.59

|

11.78

|

17.5

|

23.8

|

|

|

M:7.18 / H:3.6

|

M:14/ H:7.17

|

M:20.3 / H:10.77

|

29.4

|

43.75

|

59.5

|

|

|

M:2.0 / H:1.9

|

M:4.4 / H:3.8

|

M:6.9

/ H:6.3

|

10

|

14.7

|

19.5

|

|

|

M:6.0 / H:6

|

M:13.2 / H:11

|

M:20.7 / H:18

|

25

|

36.75

|

48.75

|

|

|

M:3000 / H:6000

|

|

Torque Constant-KT

|

N.m/

Arms

|

|

M:1.27 / H:0.74

|

M:1.18 / H:0.77

|

M:1.16 / H:0.76

|

1.29

|

1.36

|

1.36

|

|

Rotor Moment of Inertia

10-4*kgm²

|

|

M:2.59 / H:2.26

|

M:12.8 / H:11.5

|

M:18.2 / H:14.5

|

63.3

|

93.5

|

115

|

|

Mechanical Time Contant

|

ms

|

|

M:1.99 / H:2.21

|

M:1.60 / H:2.86

|

M:1.35 / H:2.06

|

4.08

|

3.20

|

1.81

|

|

|

M:2.84 / H:5.6

|

M:7.91 / H:10.75

|

M:7.95 / H:13.76

|

19.96

|

27.61

|

29.71

|

|

|

Class F

|

|

|

IP65 (When an Oil Seal is Used to be Fitted to

the Rotating Shaft)

|

|

|

FIG D

|

FIG E

|

FIG F

|

FIG G

|

FIG H

|

FIG I

|

|

|

M:4.7 / H:4.4

|

M:10 / H:9

|

M:12 / H:10.5

|

20

|

25.5

|

29

|

|

|

|

|

|

|

|

|

|

|

SD4

Servo Driver Specification

|

|

|

|

|

|

|

750W

|

1.5KW

|

2.2KW

|

3.7KW

|

5.5KW

|

7.5KW

|

|

Drive model No.

|

SD4-307M/H

|

SD4-315M/H

|

SD4-322M/H

|

SD4-337M

|

SD4-355M

|

SD4-375M

|

|

|

MA4-750M/H

|

MA4-1500M/H

|

MA4-2200M/H

|

MA4-3700M

|

MA4-5500M

|

MA4-7500M

|

|

|

380V±10% 3Ø

|

|

|

50/60

|

|

Rated Output Current

|

Arms

|

|

M:2.0 / H:1.9

|

M:4.4 / H:3.8

|

M:6.9 / H:6.3

|

10

|

14.7

|

19.5

|

|

|

M:6.0 / H:6

|

M:13.2 / H:11

|

M:20.7 / H:18

|

25

|

36.75

|

48.75

|

|

Encoder Type and Resoluation

|

|

A,B,Z,HU,HV,HW Open Collector. (A,B Phase=

128PPR)

|

|

|

0.1~60.0 Sec.

|

|

Speed

Regulation

|

Load

|

±

0.3% Below (0~Rated Torque at Rated Speed)

|

|

Voltage

|

±

0.3% Below (Source Voltage ± 10%at Rated Speed no Load)

|

|

Temperature

|

±

0.3% Below (0~45°C /32~113°F at Rated Speed no Load)

|

|

|

Sin PWM

|

|

|

1.Speed model

2.Torque mode 3.Position mode

|

|

Input

Signal

|

Analog Panel

|

1.Vref, Tref ±10V Analog Input 2.Panel VR 0~5V Analog Input

|

|

Digital Panel

|

D10~D16 and COM common, Input Impedance 4.7KΩ to

common

|

|

|

DOx Open

Collector (x=0~3), External Voltage(48VDC, 10mA below).

Magnet brake relay please set at DO3.

|

|

|

Overload, Over

Current, Over Voltage, Over Heat

Encoder Abnormal, Short Circuit

|

|

|

FIG 1

|

FIG 2

|

FIG 2

|

FIG 3

|

FIG 3

|

FIG 3

|

|

|

1.1

|

1.3

|

1.3

|

5

|

6

|

6

|

|

|

|

|

|

|

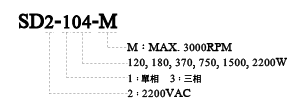

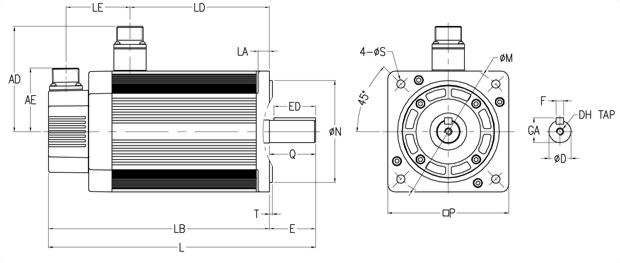

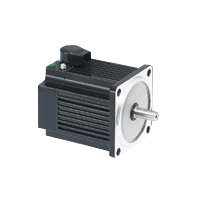

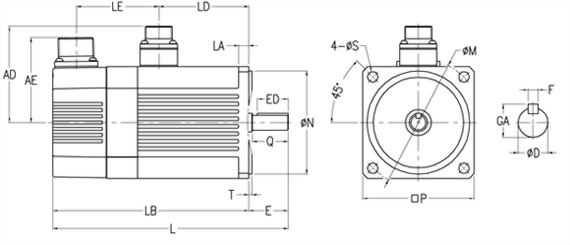

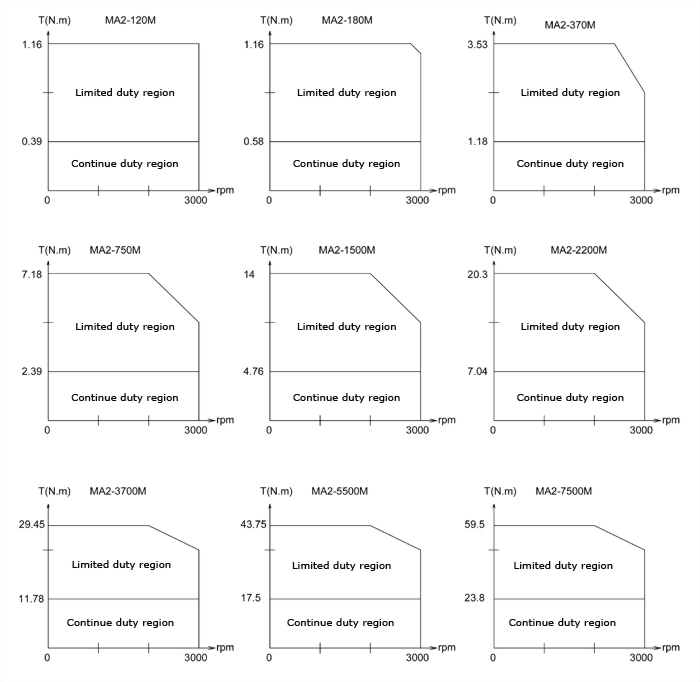

Servomotor

Motor Dimensions

|

|

|

●MA2-120M/H-MA2-750M/H

●MA4-750M/H

|

UNIT:mm

|

|

|

ØP

|

ØM

|

ØS

|

ØN

|

T

|

L

|

LA

|

LB

|

LD

|

LE

|

AE

|

AD

|

SHAFT END

|

|

ED

|

Q

|

E

|

ØD

|

GA

|

F

|

|

FIG A

|

90

|

104

|

8.5

|

83

|

2.5

|

175

|

8

|

143

|

57.5

|

66.5

|

68.6

|

77.6

|

25

|

29

|

32

|

12

|

13.5

|

4

|

|

|

14

|

16

|

5

|

|

|

190

|

158

|

72.5

|

|

|

245

|

213

|

127.5

|

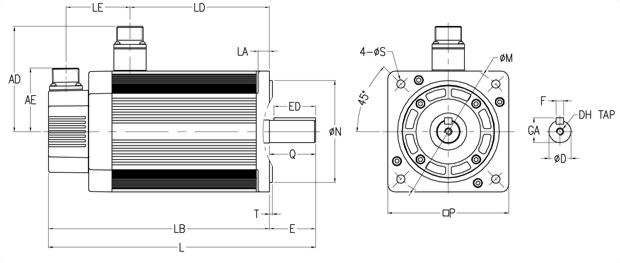

●MA2-1500M/H-MA2-2200M/H

●MA4-1500M/H-MA4-2200M/H

|

UNIT:mm

|

|

|

ØP

|

ØM

|

ØS

|

ØN

|

T

|

L

|

LA

|

LB

|

LD

|

LE

|

AE

|

AD

|

SHAFT END

|

|

ED

|

Q

|

E

|

ØD

|

GA

|

F

|

DH

|

|

FIG E

|

130

|

145

|

9

|

110

|

3.5

|

261.5

|

12

|

211.5

|

123.5

|

69

|

68.6

|

113.3

|

45

|

50

|

50

|

24

|

27

|

8

|

M8

|

|

|

288.5

|

238.5

|

150.5

|

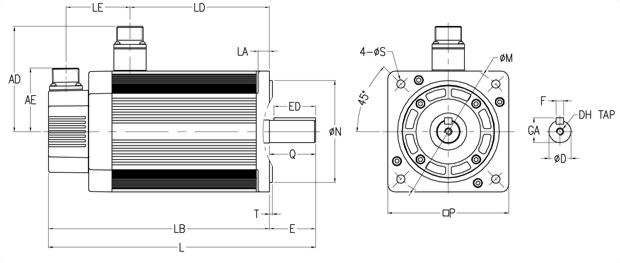

●MA2-3700M-MA2-7500M

●MA4-3700M-MA4-7500M

|

|

|

|

ØP

|

ØM

|

ØS

|

ØN

|

T

|

L

|

LA

|

LB

|

LC

|

LD

|

LE

|

AB

|

AC

|

AD

|

AE

|

KK

|

SHAFT END

|

|

ED

|

Q

|

E

|

ØD

|

GA

|

F

|

DH

|

|

FIG G

|

180

|

200

|

13.5

|

114.3

|

4

|

359.5

|

18

|

280.5

|

261.5

|

107

|

111

|

111

|

116.5

|

147

|

68.6

|

32.8

|

65

|

73

|

79

|

35

|

38

|

10

|

M12

|

|

|

454.5

|

341.5

|

322.5

|

168

|

90

|

108.5

|

113

|

42

|

45

|

12

|

M16

|

|

|

484.5

|

371.5

|

352.5

|

198

|

|

|

|

|

|

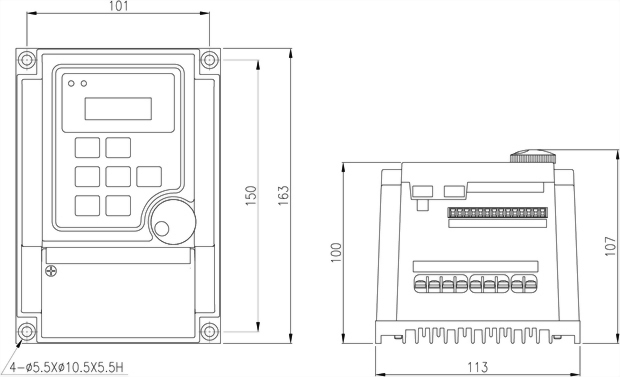

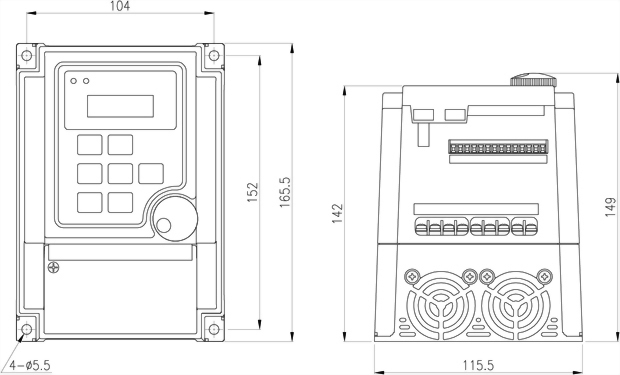

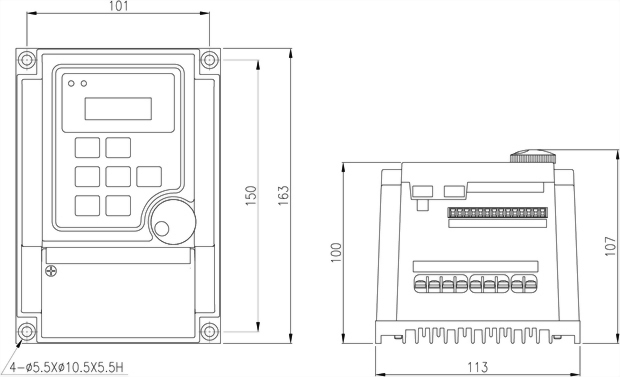

●SD2-101M/H~SD2-107M/H

●SD2-115M/H~SD2-122M/3H

●SD4-307M/H~SD4-322M/H

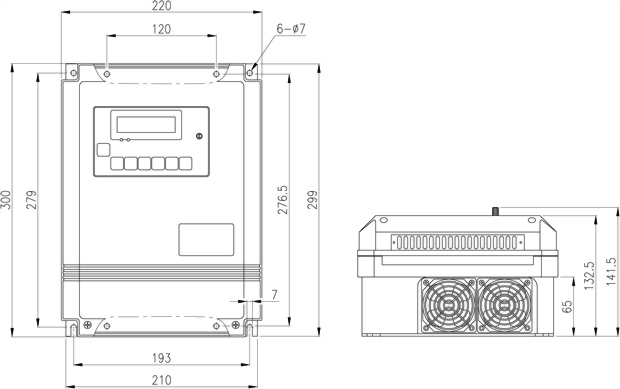

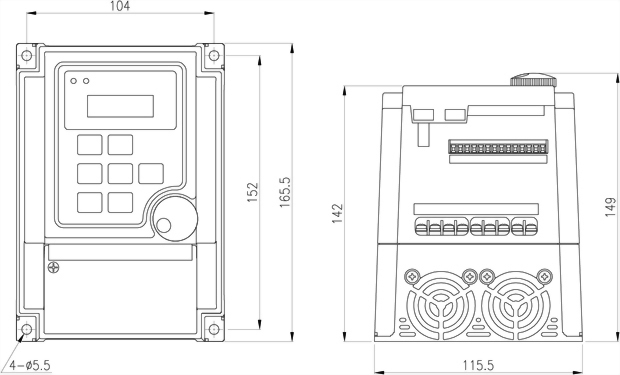

●SD2-337M~SD2-375M

●SD4-337M~SD4-375M

|

|

|

|

|

|